Reliable Plastic Injection Molding Service.

Competitive Price And High Quality Guarantee.

Production Ability

1. The part weight is from 0.1g to 1500g.

2. Molding up to 128 parts at a time.

3. The part tolerance is 0.1% of the size.

4. The wall thickness is from 0.5mm to 20mm.

5. Multi-material injection molding.

6. Plastic parts assembly capability.

7. Surface treatment of plastic parts.

8. Provide solutions for complex parts.

Service Features

Service & Experience

7*24 hours online service;

Free DFM service;

20 years of industry experience;

Time & Delivery

DFM: 0.5-2 working days;

T1 model: 4-8 weeks;

Prototype/rapid mold: 7-14d;

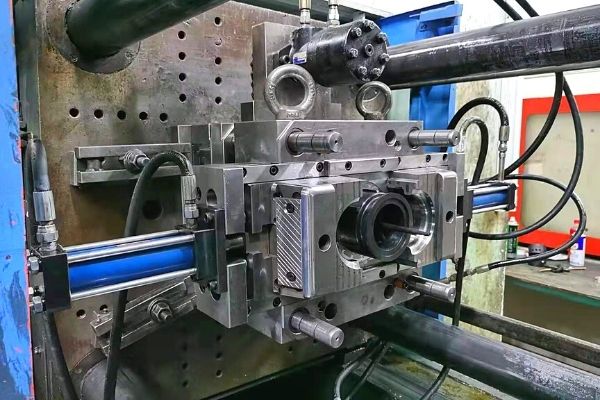

Equipment & Personnel

Stable and reliable equipment;

Machine pressure: 60-600 tons;

Personnel: 5 years of experience;

Production & Quality

Monthly delivery: 3000000pcs;

Qualification rate: 99.9%;

Spare parts: 1%-2%;

Product Show

Quality Management

1. Check the materials.

2. Save the correct sample for comparison.

3. The engineer issues an operation manual.

4. Visually inspect and record each plastic part.

5. Take samples for further confirmation in the laboratory.

6. Check and record again before leaving the factory.

7. Organize quality control/quality inspection records for reference.

Our Goal: to maintain the consistency of the quality of plastic parts. Every plastic part is traceable, so any defects can be found quickly and properly handled.

Surface Treatment of Plastic Parts

We provide surface treatment to meet your individual needs for plastic parts.

Services include:

- UV coating

- Painting

- Polishing

- Silk screen/pad printing

- Labeling

- Chrome Plasting

- Laser etching

Value-added Services

Assist Development

We can design and develop for your project. No need to find a third party, you just need to tell us what your idea.

Assistance Purchase

We assist you in purchasing resource to reduce your work. This is our free service.

One-Step Service

We can undertake the final assembly and packaging of the product. To shorten the project time.