Mold design should understand the working principle of the part. It is necessary to know how to design properly so as to avoid problems with the designed mold. The existence of these problems will seriously affect the quality of the mold. We need to pay enough attention.

Here are nine tips for optimizing the basics of design. These content will be inspiring and helpful to inexperienced designers.

1.Powerful design thinking

Due to the diverse design of the plastic parts, the same mold has almost no. However, there are several design options for the mold structure of the same product. Choose the best solution and pursue the balance between mold quality and cost. Establish a strong sense of innovation and exercise design thinking.

2.Do not violate the design principles.

1)The design should follow the principle of reliable structure. Prevent the mold from failing prematurely.

2)Properly and rationally design molds and parts.

3)Prevent conceptual Design error. For example. the size of the hole allows only positive values. and the size of the axis allows only negative values. Its unlabeled tolerance value is HT12 accuracy.

3.Dimensions numbers cannot be set arbitrarily.

1)The dimensions of the part cannot be designed to be decimal.

2)The position size of the part cannot be designed as a decimal (such as the cooling water hole pitch).

3)The center distance of two parts can not be designed as a decimal.

4)The value of the angle should be reasonable.

These can cause unnecessary troubles in manufacturing.

4.Mold design cost optimization.

1)The shape of the template should not be too large and the thickness should not be too thick. Otherwise, materials are wasted and manufacturing costs are increased. In particular, the size of large molds cannot be enlarged at will.

2)Large molds should pay more attention to the rationality of mold shape and structural design.

3)Steel selection needs to consider economics and practicality. Reasonable selection of steel and heat treatment processes.

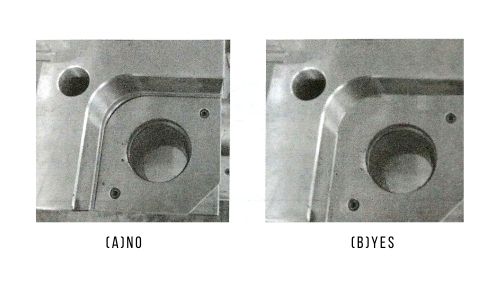

5. Design should consider processing costs.

The design should consider processing costs. Avoid unreasonable design. As shown in Figure (a). The steps next to the guide sleeve are incorrectly designed. Both increase processing costs and are not aesthetically pleasing. It should be changed to Figure b.

6.The mold part design is not beautiful.

Streamline the structure within a reasonable range. Ensure the integrity and coordination of the structure.

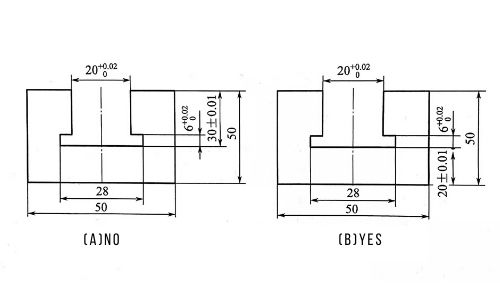

7.Reasonable design benchmarks.

Properly set the datum for design. As shown in Figure A. The dimension is incorrect and the datum should be on the underside. As shown in Figure B. In some multi-cavity mould designs, the center hole size of the product is designed to be a decimal. Or the mold reference setting is incorrect. This brings a lot of unnecessary trouble to post processing and measurement.

8.The design did not take into account the relevant factors of mold failure.

There are two kinds of failures of the mold: normal failure and abnormal failure. Abnormal failure has the following factors.

1.The structure of the mold is unreasonable and the design of the parts does not meet the requirements.

2.The manufacturing precision of the parts is poor and the assembly quality of the mold is poor.

3.The mold strength and rigidity are not enough.

4.Improper selection of steel and improper heat treatment. Causes the mold to crack and fail in advance.

5.Improper use and maintenance of the mold, premature failure.

9.There are no rules and differences in 3D modeling colors.

In the design of the mold structure. The 3D modeling color is not clearly defined and distinguished. If the 3D modeling color of the product and the mold. It will make the readers who see the shape understand the mold structure at a glance.

At the end

These 9 guidelines are the most basic about mold design. It is aimed at inexperienced designers. Mould design should consider more details. Self-examine through these 9 guidelines. Improve design thinking. If you still have questions, please contact us.