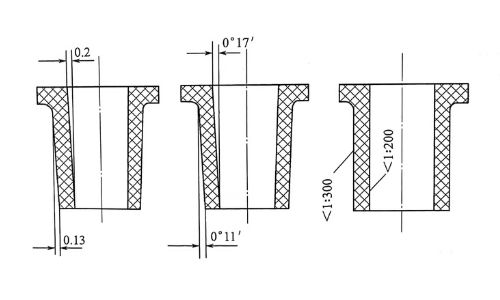

In order to smoothly ejection the plastic part from the cavity and the core during mold opening. The inner and outer surfaces of the plastic part must be bounded by the parting line of the mold, and a reasonable draft angle should be set. The draft angle of plastic part prevents the plastic parts from sticking to the mold, which causes the plastic part to deform. The draft angle is generally 3°-5°.As shown below.

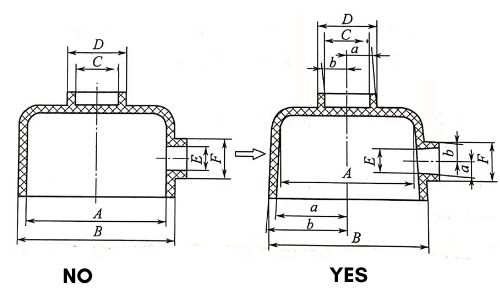

The draft angle of the inner and outer sides of the plastic part is different.

The inner side and the outer side of the plastic part are ejection in the same direction. Draft angle of the female mold should be larger than the draft angle of the male mold. The purpose of this is to leave the plastic part in the male mold and facilitate the ejection of the plastic part. As shown below.

The size of the draft is selected according to the geometry of the plastic part.

1.The higher the height of the plastic part, the deeper the hole, and the plastic part with more forming holes takes a larger draft angle.

2.A plastic part with a large wall thickness can take a larger value.

3.For products with higher precision requirements, avoid excessive draft angle.

Select the appropriate draft angle according to the plastic material.

The draft angle should be selected according to the type and rigidity of the plastic. Hard plastics and plastics with large shrinkage have a large draft angle. For reinforced plastic products, a large draft angle should be used, and the draft angle is generally 1°-1°30′.

| Plastic Material | Draft Angle | |

|---|---|---|

| Cavity | Core | |

| PE,PP,Soft PVC | 45°~1° | 30′~45′ |

| ABS,PA,POM,Chlorinated polyether | 1°~1°30′ | 40′~1° |

| PS,PMMA,PC,Hard PVC | 1°~2° | 50′~1°30′ |

| Thermoset Plastic | 40′~1° | 20′~50′ |

The side of the product is textured, and the draft angle is related to the depth of the texture.

If the draft angle is not large enough, the plastic surface is prone to burrs and whitening. Below are the draft angles for different surface requirements.

1.The matte surface has a draft angle of 2 degrees or more.

2.Textured surface draft angle is 3°-5°.

3.The draft angle of the text and pattern is 8°-10°.

4.The draft angle of the symbol surface is greater than 10°

5.The draft angle of the symbol surface is greater than 10°

Textured depth and corresponding draft angle

| Number | Texture depth(in) | Minimum draft angle(°) | Number | Texture depth(in) | Minimum draft angle(°) |

|---|---|---|---|---|---|

| MT-11000 | 0.0004 | 1.5 | MT-11200 | 0.003 | 4.5 |

| MT-11010 | 0.001 | 2.5 | MT-11205 | 0.0025 | 4 |

| MT-11020 | 0.0015 | 3 | MT-11210 | 0.0035 | 5.5 |

| MT-11030 | 0.002 | 4 | MT-11215 | 0.0045 | 6.5 |

| MT-11040 | 0.003 | 5 | MT-11220 | 0.005 | 7.5 |

| MT-11050 | 0.0045 | 6.5 | MT-11225 | 0.0045 | 6.5 |

| MT-11060 | 0.003 | 5.5 | MT-11230 | 0.0025 | 4 |

| MT-11070 | 0.003 | 5.5 | MT-11235 | 0.004 | 6 |

| MT-11080 | 0.002 | 4 | MT-11240 | 0.0015 | 2.5 |

| MT-11090 | 0.0035 | 5.5 | MT-11245 | 0.002 | 3 |

| MT-11100 | 0.006 | 9 | MT-11250 | 0.0025 | 4 |

| MT-11110 | 0.0025 | 4.5 | MT-11255 | 0.002 | 3 |

| MT-11120 | 0.002 | 4 | MT-11260 | 0.004 | 6 |

| MT-11130 | 0.0025 | 4.5 | MT-11265 | 0.005 | 7 |

| MT-11140 | 0.0025 | 4.5 | MT-11270 | 0.004 | 6 |

| MT-11150 | 0.00275 | 5 | MT-11275 | 0.0035 | 5 |

| MT-11160 | 0.004 | 6.5 | MT-11280 | 0.0055 | 8 |

The release angle in the table is determined based on ABS plastic. In actual use, it should be adjusted according to the molding conditions, molding materials, and wall thickness.

At the end

Plastic parts should be set to a reasonable draft angle. Refer to the shape, material, molding conditions, wall thickness, surface texture, etc. of the plastic part. If you still have questions, please contact us.