What is the Stacked injection mold

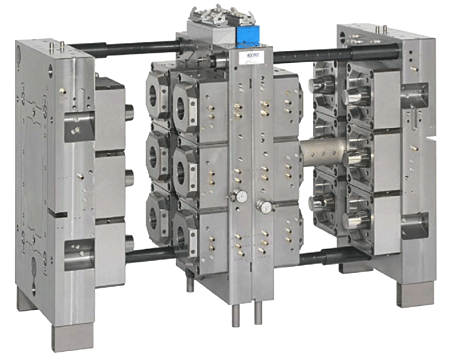

Stacked injection molds are different from ordinary injection molds.It is a special mold structure. The stack injection mold has a plurality of parting surfaces, and each parting surface can have one or more cavities.Multiple cavities are arranged in a mold in the mold clamping direction.The lamination injection mould consists of a gating system, a die frame system, a cooling system, a bearing guiding positioning system, a two-way ejection system, and an opening and closing module linkage system.

The basic structure of the Stacked injection mold

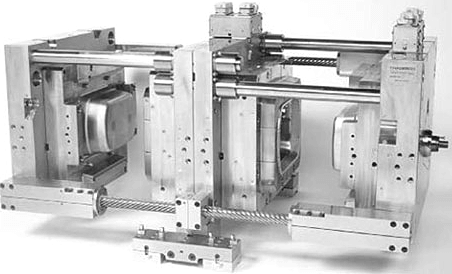

Stacked injection mold consists of moving mold, middle mold and fixed mold.

Multi-layer injection mold consists of moving mold, middle mold and fixed mold.

fixed mold is located on the right side of the mold.It is fixed on the fixed plate of the injection molding machine. One port of the gating system is in contact with the injection molding machine.The fixed part of the flow channel is provided with a heating element, so that the material in the fixed mold flow channel maintains a molten state.The hot runner system extends through the fixed part. When the mold is closed, it is connected to the mouth of the injection molding machine.Thus the flow passage extension portion must have sufficient length. Ensure that no melt leaks out during mold opening.

Middle model consists of a frame with a hot runner inside and a cavity plate with two outer surfaces of the molded part.Its gating system has thermal nozzles on both sides.The middle mold needs to be guided and supported, and the ejector mechanism is provided on each side of the movable mold and the fixed mold.During the demolding process, the intermediate plate is moved with additional moving parts so that the middle mold is between the moving mold and the fixed mold.The middle mold hot runner system is similar to a conventional hot runner. Consists of nozzles, manifolds, hot runner plates, and heating devices.

Moving mold is on the left side of the mold.The moving mold moves with the injection mold platen during mold opening. The middle part is driven by the linkage device. Let both parting surfaces open at the same time.

Stacked injection mold features

-

- Productivity, Stacked injection mold is twice as much as ordinary mold.Significantly reduced the cost of injection molding and increased the production of plastic parts per unit time.

- The Stacked injection mold may be mounted on the same single injection mold injection molding machine.No need to buy extra equipment. Save on the costs of machines, factories, and labor.

- Stacked injection mold manufacturing requirements are basically the same as ordinary molds. But the manufacturing what does winstrol do time is 5%~10% shorter than the two single-layer molds.

- Stacked injection molds are suitable for large-scale production of flat-shaped large plastic parts, small multi-cavity thin-walled plastic parts.The greater the quantity, the lower the production cost of plastic parts.

Gating system

The Stacked injection mold casting system can use a cold runner pouring system and a hot runner pouring system.Hot runner system can transfer injection pressure well. It helps to transfer the molding quality of plastic parts. Easy to automate production. However, there are certain requirements for plastic varieties and they are expensive.

When using a cold runner system, the molding quality of the plastic parts is poor. Can not be automated production. However, the processing is easy and the cost is low.Due to the multi-layer injection mold, the main channel is longer. In order to reduce the injection time, increase productivity. At present, hot runner gating systems are often used.

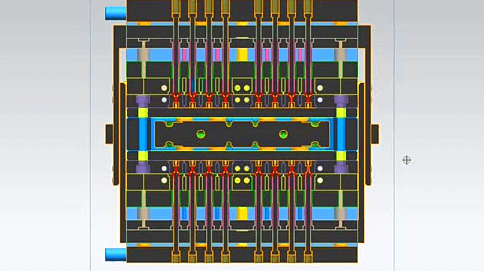

Temperature control system

Mold temperature is one of the important factors that affect the molding quality and molding time of plastic parts. When designing a Stacked injection mold, it is necessary to ensure that the temperature conditions of all layers of the cavity are the same. In order to reduce the heat loss due to heat conduction in the hot runner system, the contact area should be reduced and the insulation pad should be provided.The key points of the design of the Stacked injection mold cooling system are as follows:

- Mold cooling time is reduced to the shortest

- The plastic parts are evenly cooled, reducing the deformation of the plastic parts.

- Auxiliary cooling channels can be provided in both the injection mold core and the core insert

- Cooling channels can also be installed in the middle mould. Take away radiant heat from the gating system.

Mold opening mechanism

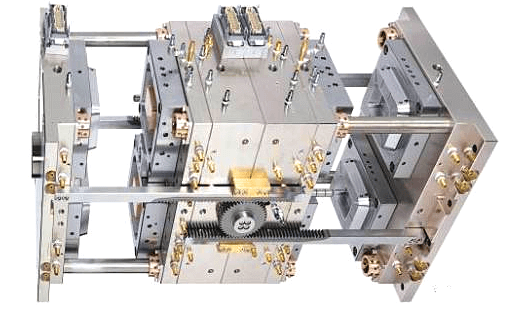

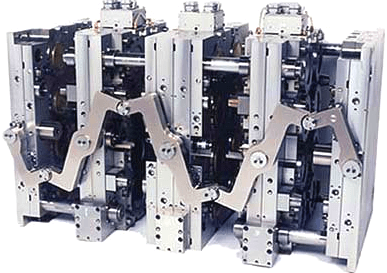

In order to make the plastic contraction consistent. The residence time of plastic parts in the cavity should be equal.Therefore, Stacked injection mold should ensure that the parting surfaces of all cavities are opened at the same time.There are usually three situations:

- Rack and pinion drive

- Link drive

- Hydraulic cylinder drive

The gear transmission mechanism and the mechanical linkage mechanism are often used as a lamination mold for the injection mold. The former has better technical performance and is also economical. However, the latter has great flexibility. Hydraulically assisted mold opening makes it easier to control mold opening time. But the structure is larger. Need to take the oil road, easy to cause pollution.

Guide mechanism design

Stacked injection molds have a large number of partitions and more moving plates. Therefore, the demand for guide institutions is high. 8 shoulder guide posts are generally used. Four 1 components are mounted on the moving and fixed molds. With the active cavity plate and guide sleeve on the stripper template to ensure good guidance and positioning.

Ejection system

The dynamic mold removal mechanism is the same as the normal mold. The plastic parts are pushed by push rods. Fixed mold using hydraulic drive, tie rod, chain and other methods.